Dr.M.Geeta Rani, HOD

About Mechanical Engineeringring

DEPARTMENT OF MECHANICAL ENGINEERING

Mechanical engineering is one of the most comprehensive professional disciplines. Mechanical engineering principles are employed in a wide range of industries such as power generation, manufacturing, energy, repair and maintenance, automation and control, robotics, electronics, nanotechnology, food industries, automotives, petroleum, aerospace, etc. Over the last one decade, we have grown our expertise and competence in the core Mechanical Engineering and research.

Our primary importance is to motivate, inspire, and build trust and confidence in students. We impart quality engineering education through sound theoretical knowledge, hands-on experience in the laboratories as well as computational skill and exposure to recent technologies by visiting industries & expert talk. We provide opportunities for students to participate in various technical and sports events /competitions. This is an attempt to highlight the achievements of the department.

Vision of the Department

To become a competence center in the Mechanical Engineering discipline with strong academic and practical environment to reach the varying and stimulating needs of the current industry, research organizations, imparting social values to serve the society.

Mission of the Department

M1 - To deliver technical education leading to careers as Mechanical Engineering professionals in various fields.

M2 - To develop human resources required to analyse, design, manufacture and optimize the performance of mechanical, thermal and manufacturing systems.

Mechanical Engineering at a Glance

Discover the numbers that reflect our commitment to excellence in education

Our Faculty

Meet our distinguished faculty members who bring expertise and excellence to every classroom.

Labs & Facilities

State-of-the-art laboratories equipped with modern technology to support hands-on learning and research

MOS LAB

The Mechanics of Solids and Metallurgy Lab introduces students to the fundamental mechanical behaviour of materials and the micro structural characteristics that determine their strength, ductility, and performance.It helps students connect theory with practical testing and understand how materials respond under different loading and environmental conditions.

Engineering Work Shop practice

Engineering Workshop Laboratory – Description

The Engineering Workshop Laboratory is an essential part of the first-year engineering curriculum. It introduces students to the fundamental manufacturing and fabrication processes used in engineering practice. The lab aims to provide hands-on experience with various tools, equipment, and techniques used in mechanicalrelated engineering fields.

Objectives

To familiarize students with the basic workshop practices and safety procedures.

To develop practical skills in using tools, machines, and instruments.

To help students understand the working principles of different manufacturing processes.

To bridge the gap between theoretical knowledge and real-world applications.

Major Sections of the Workshop

1. Carpentry Shop – Practice in wood cutting, planning, chiseling, and assembling joints like dovetail and mortise & tenon.

2. Fitting Shop – Learning to use hand tools such as files, hacksaws, and vices to make fitting joints in metals.

3. Sheet Metal Shop – Working with thin metal sheets to make objects like trays, funnels, and boxes.

4. Welding Shop – Introduction to arc and gas welding processes for joining metals.

5. Foundry / Casting Shop – Learning about pattern making, sand moulding, and basic casting techniques.

6. Electrical Engineering Basics – Basic wiring, soldering and testing simple electrical circuits.

Learning Outcomes

By the end of the workshop, students will be able to:

• Identify and operate basic tools and machines used in workshops.

• Demonstrate safe and efficient work habits.

• Fabricate small components independently.

• Gain appreciation for precision, accuracy, and workmanship in engineering.

Applications

The skills acquired in the Engineering Workshop Lab are fundamental for all branches of engineering. They serve as the foundation for courses in mechanical design, manufacturing, prototyping, and maintenance engineering.

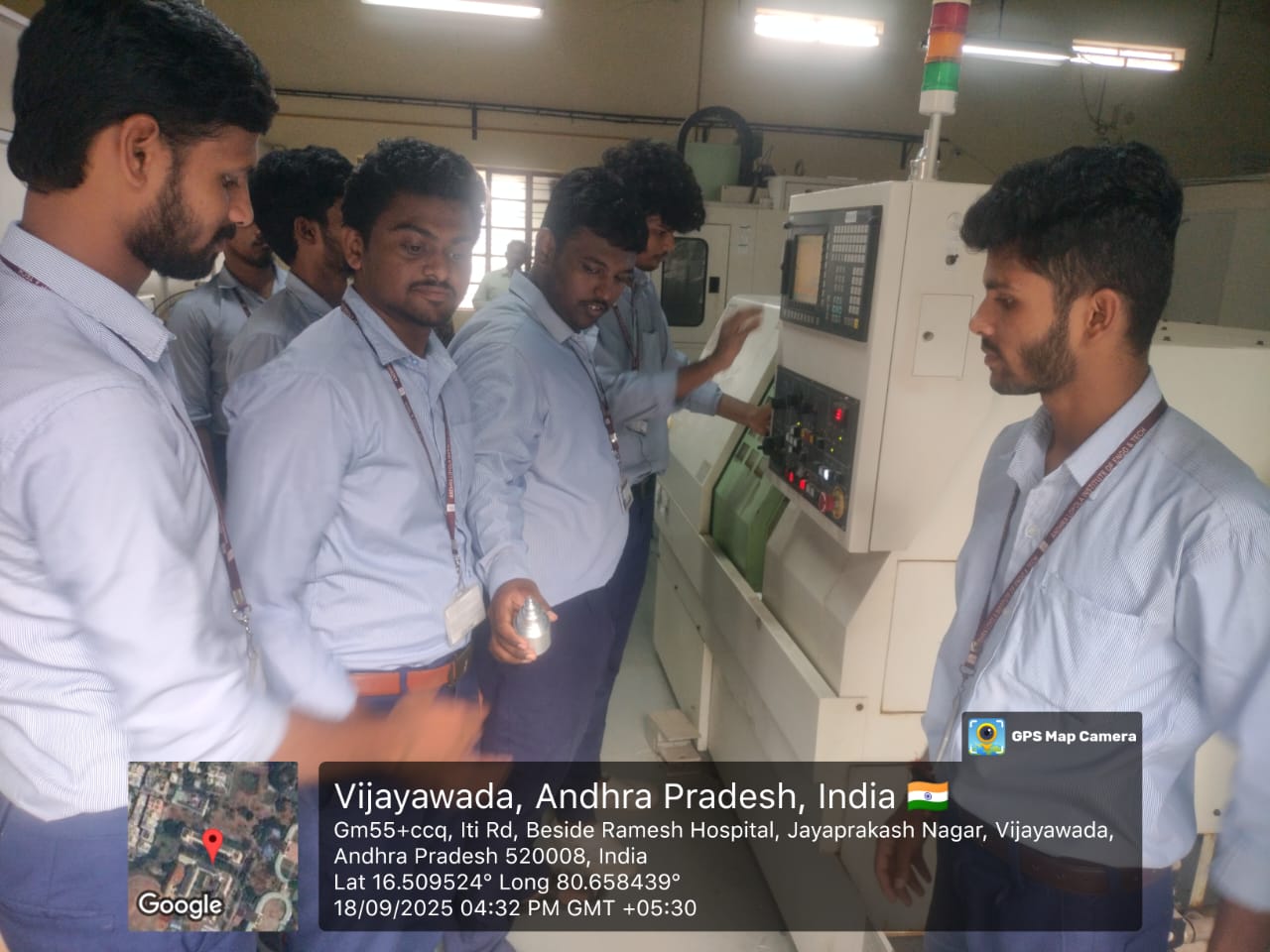

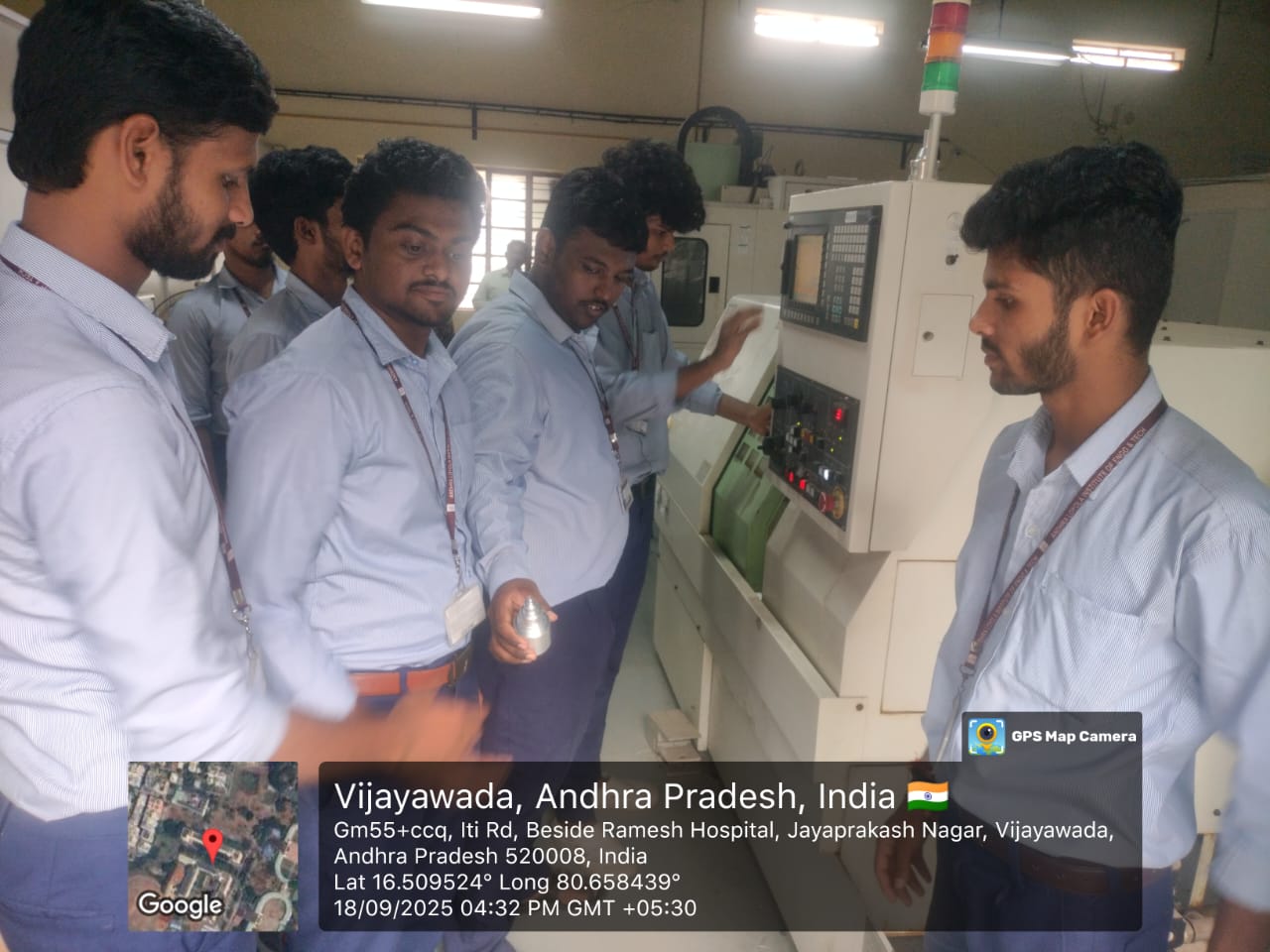

CAD-CAM LAB

The Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) Laboratory is a vital part of the engineering curriculum, designed to bridge the gap between design and manufacturing processes. This lab enables students to transform innovative ideas into real-world products using advanced design and manufacturing technologies.

The laboratory is equipped with modern CAD software such as AutoCAD, and Creo for 2D drafting and 3D modeling, along with CAM tools for simulating machining and production processes. Students gain hands-on experience in product design, modeling, assembly, tool path generation, and CNC programming.

Metrology & Instrumentation Lab

metrology and instrumentation lab is a specialized facility where students and professionals learn to measure, calibrate, and analyze physical quantities using various tools and instruments. It plays a crucial role in engineering education, especially in fields like mechanical, electrical, and electronics engineering.

Purpose and Importance

Metrology is the science of measurement, and instrumentation involves devices used to measure, control, and monitor variables such as length, temperature, pressure, and electrical quantities. The lab trains individuals to achieve accuracy, reliability, and repeatability in measurements, which is essential for research, quality control, and industrial processes.

FM & HM LAB

The Fluid Mechanics and Hydraulic Machines Laboratory is designed to help students understand the fundamental principles of fluid behavior and the operation of various hydraulic machines. The lab provides practical exposure to the measurement of fluid properties, flow characteristics, and performance testing of hydraulic devices.

Students perform experiments to determine fluid parameters such as pressure, flow rate, and losses in pipes. They also study the working of turbines, pumps, and other hydraulic machines to evaluate their efficiency and performance under different operating conditions.

This lab enables students to correlate theoretical concepts with real-time applications in the fields of civil, mechanical, and electrical engineering, especially in systems involving fluid transport, water power, and hydraulic energy conversion.

Theory of Machines lab

Theory of machine lab gives the knowledge & skills related to machine, mechanism & motions according to field applications. Explain and discus inversions of four bar, single slider and double slider chain. Explain and demonstrate cam and followers arrangements available in laboratory and plot displacement v/s angle of rotation curve for these. Determine co-efficient of friction of different materials using two roller oscillating arrangement and differentiate among. Explain the principle and verify the practical vs. theoretical torque relation for gyroscope and its applications. Explain static and dynamic balancing.

Mechatronics Lab

Our Mechatronics Laboratory is equipped with modern training kits and advanced software to provide hands-on experience in automation and control systems. The lab features Trainer Kits such as Traffic Signal Control, Water Level Controller, Lift Control System, and Conveyor Control using PLCs, which help students understand real-time industrial automation processes. Using Automation Studio software, students design and simulate various hydraulic and pneumatic circuits like series, parallel, meter-in, and meter-out systems. In addition, MATLAB programming is integrated into lab activities to develop analytical and simulation skills, enabling students to bridge the gap between mechanical and electronic system design.

Machine Tools Lab

This laboratory aims to equip students with the ability to:

Understand the components, construction, and operational envelope of major general-purpose machine tools, enabling them to comprehend the variety of product shapes and features that can be produced.

Develop proficiency in using precision instruments to measure critical dimensional features such as bores, angles, and tapers on machined parts.

Execute standard alignment and performance tests on various machine tools to ensure accuracy, safety, and optimal operational standards.

List of Practical Experiments

Students will conduct a minimum of six experiments covering the following core areas of machining:

Machine Introduction: Detailed study and identification of the parts and functions of key machines: Lathe, Drilling, Milling, Shaper, Planing, Slotting, Cylindrical Grinder, Surface Grinder, and Tool and Cutter Grinder.

Lathe Operations: Hands-on execution of essential turning processes, including Step Turning, Knurling, Taper Turning, Thread Cutting, and Drilling on the lathe.

Drilling Operations: Performing standard hole-making and finishing processes: Drilling, Reaming, Tapping, Rectangular Drilling, and Circumferential Drilling.

Specialized Machining: Execution of complex shaping and slotting features, such as converting round stock to square and hexagonal forms on the shaper, and cutting Keyways (T-slot) on the slotter.

Milling Operations: Practical work involving precision movement and complex geometry generation, specifically Indexing and the operation of manufacturing Gears.

Course Outcome

At the end of the course, students will be able to:

Gain comprehensive knowledge about the construction and operational parts of various machine tools and expertly determine the different shapes of products that can be produced using them.

Production Technology Lab

This laboratory course is meticulously designed to provide students with essential, hands-on mastery of fundamental Manufacturing Processes critical to modern engineering. The curriculum focuses on developing the practical competencies required to select, execute, and analyze various fabrication techniques.

Course Objectives

Upon successful completion of the MPL, students will be able to:

● Acquire operational proficiency in the core manufacturing domains: Metal Casting, Welding and Joining, Press Working, and Polymer Processing.

● Evaluate and quantify the mechanical characteristics of molding materials by performing rigorous Sand Properties Testing (e.g., Sieve analysis, strength, and permeability tests).

● Develop skills in pattern design and mould preparation for producing components via sand casting.

● Execute and analyze various contemporary welding techniques (MMAW, TIG/MIG, Spot welding) and low-temperature joining methods (Brazing and Soldering).

● Demonstrate competence in material forming through Sheet Metal Operations and understand advanced processes like deep drawing and extrusion.

● Operate equipment for plastics processing (Injection and Blow Molding) and gain foundational experience with Additive Manufacturing (3D Printing).

This lab ensures students bridge the gap between theoretical knowledge of materials science and the practical requirements of engineering design and fabrication.

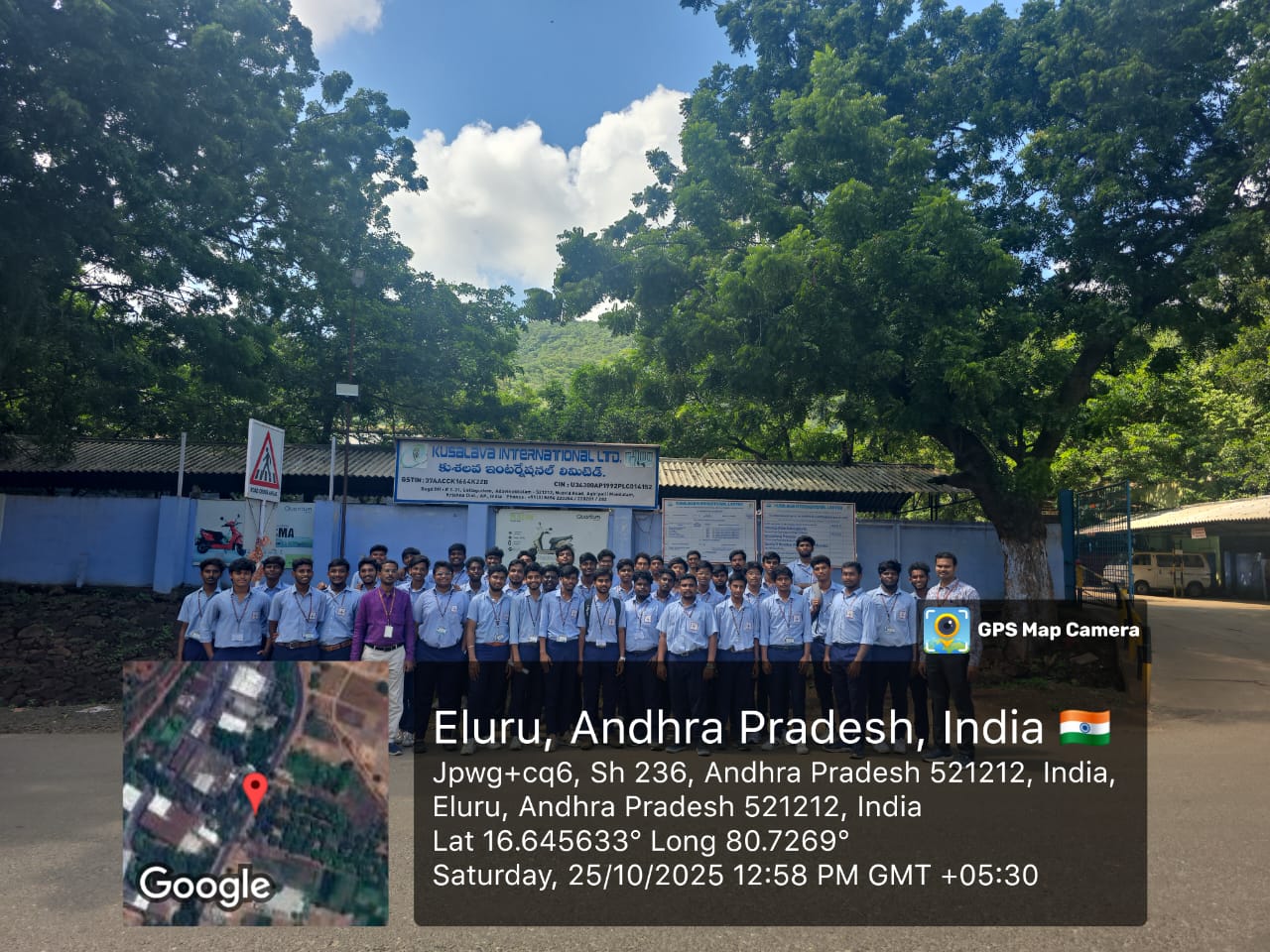

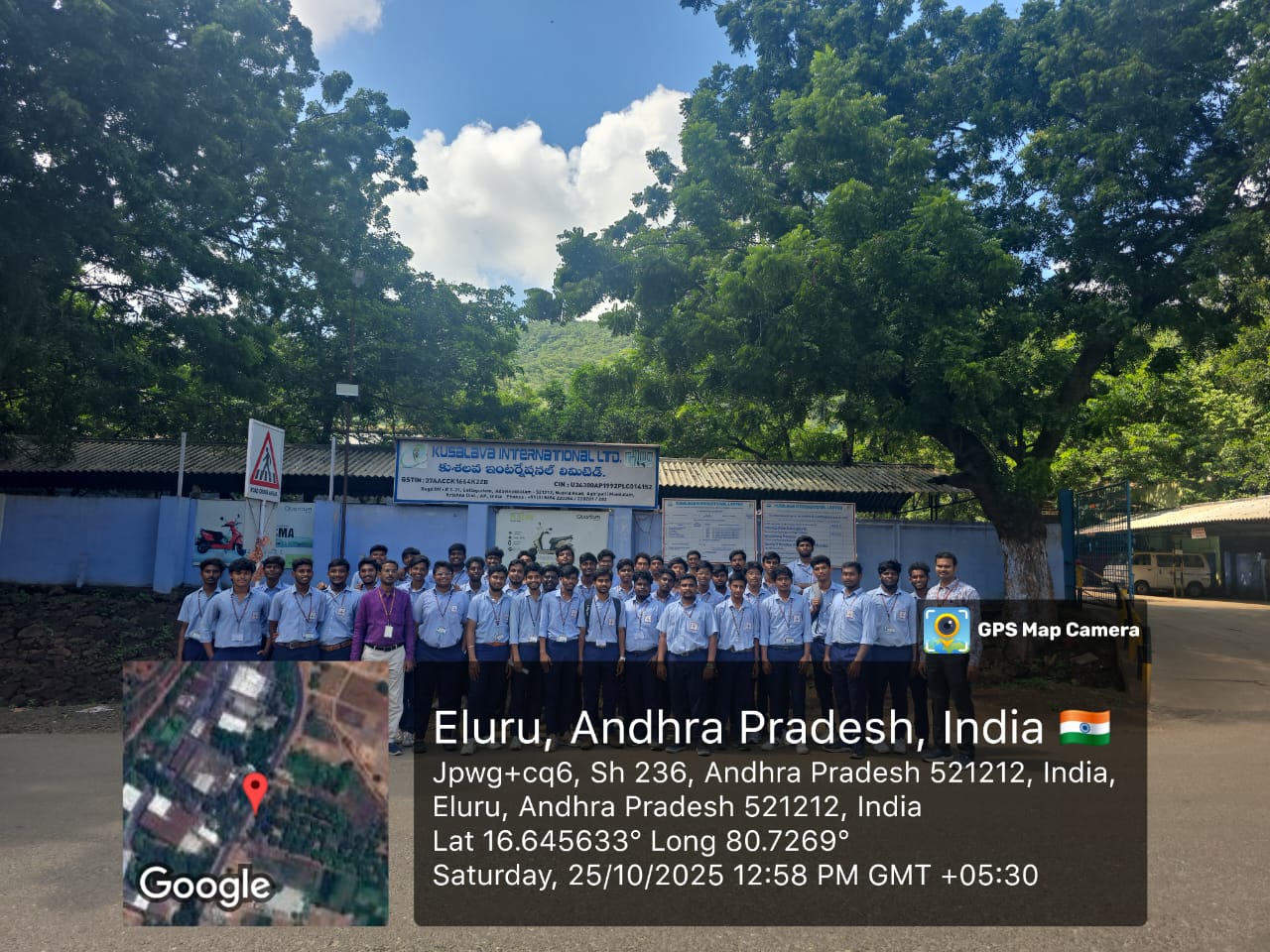

Events & Gallery

Showcasing our vibrant campus life, technical events, workshops, and student achievements

Quick Links

Essential resources curated for this department.

No Quick Links Available

Quick links for this department haven’t been configured yet.